Aluminium Billet Manufacturing

Aluminium Billet manufacturing involves a meticulous process of casting, homogenizing, and extruding. The raw aluminium is first melted and cast into cylindrical billets. These billets undergo homogenization to enhance their internal structure and alloy properties. The final step is extrusion, where the billets are forced through a die to create specific shapes. Precision and control during each phase are crucial to producing high-quality billets.

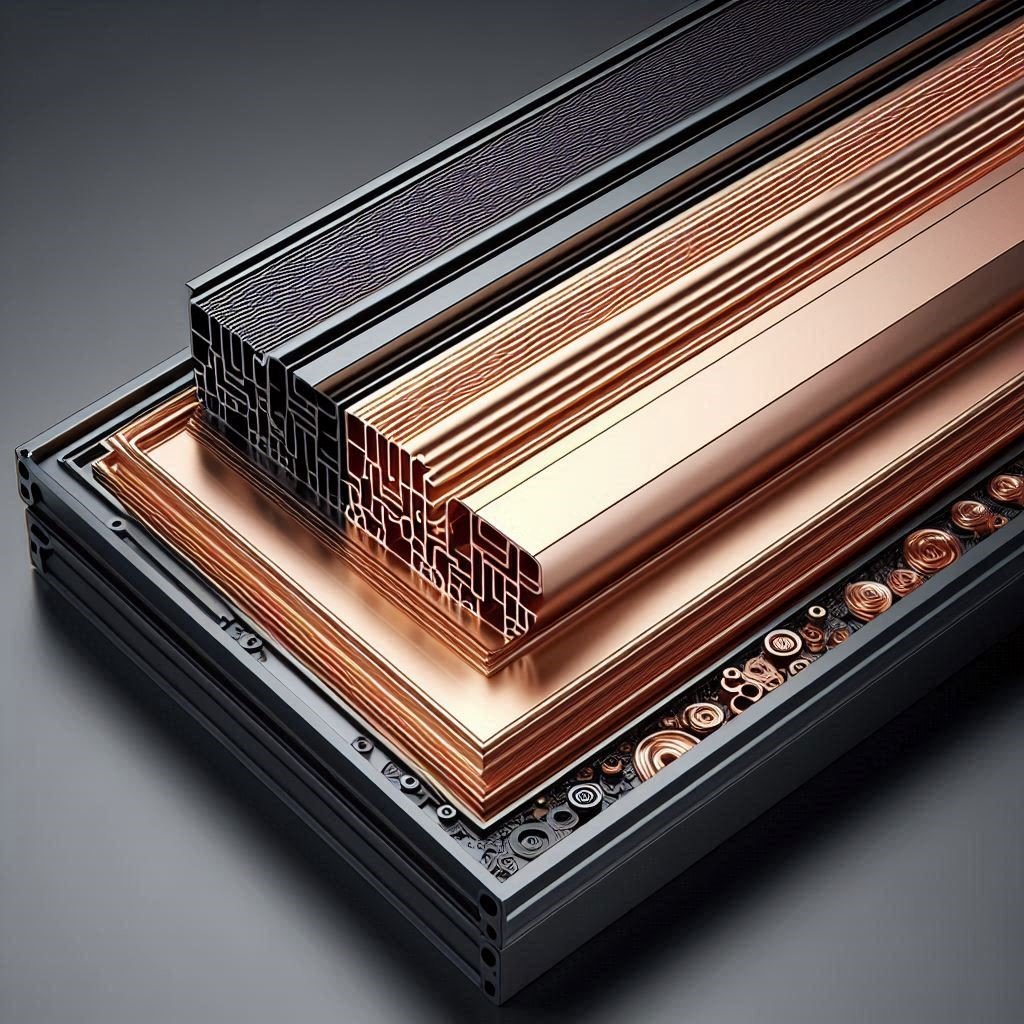

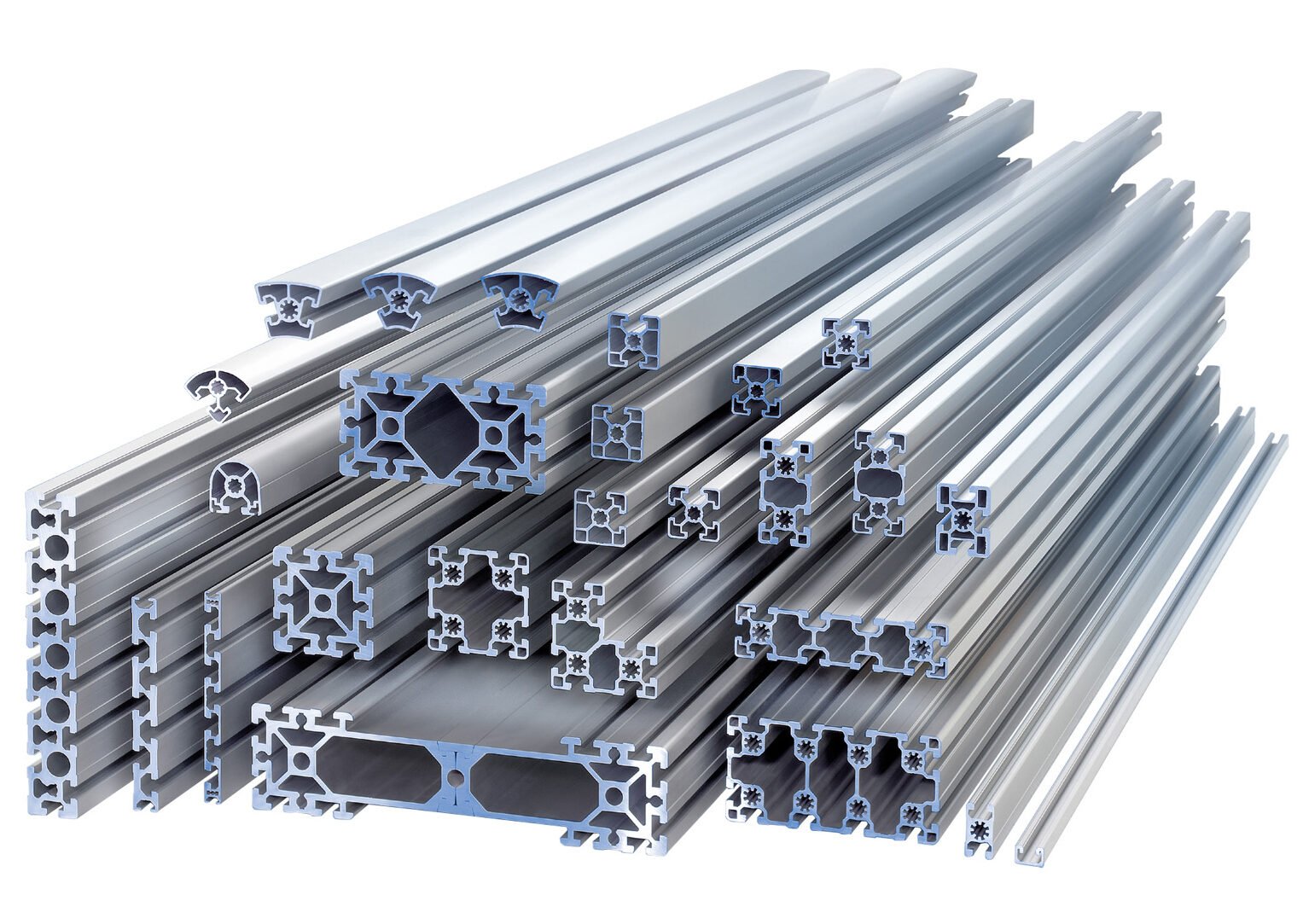

Aluminium Extrusion manufacturing

Aluminium extrusion manufacturing is an advanced process that transforms aluminium billets into desired profiles. This process begins with heating the billets to a malleable temperature. The heated billets are then forced through a die using a powerful hydraulic press, creating long shapes with consistent cross-sections ranging from simple to complex geometries.

The versatility of aluminium extrusion allows for a wide range of applications, including construction, automotive, aerospace, and consumer goods. During extrusion, careful attention is given to the temperature, pressure, and speed to ensure the final product meets precise specifications. Post-extrusion treatments, such as anodizing or powder coating, may be applied to enhance surface properties and appearance.

Overall, aluminium extrusion manufacturing is a vital technique in producing durable, lightweight, and customisable aluminium components.

Tool Room for Aluminium Extrusion Tools

The tool room for aluminium extrusion tools plays a pivotal role in the manufacturing process, ensuring precision and efficiency. This specialized area is dedicated to the creation, maintenance, and storage of extrusion tools essential for transforming aluminium billets into desired profiles. The tool room’s function is multifaceted, encompassing the design, fabrication, and upkeep of dies and other critical components. By meticulously managing these tools, the tool room ensures the consistency and quality of the final extruded products, meeting precise specifications required for diverse applications in construction, automotive, aerospace, and consumer goods industries.

Cut to Length

At Beyond Lineals, we offer cut-to-length services to provide aluminium profiles in the exact dimensions required by our customers. Precision cutting ensures minimal waste and optimal use of materials. Profiles upto 7 meter in length and Diameter/Rectangle upto 12 inches can be processed.

Grinding

Our comprehensive grinding services include ID grinding, OD grinding, face grinding, and finish grinding. These precision techniques are essential for achieving the exact tolerances and surface finishes required by our customers. Whether it’s internal diameters, external diameters, flat surfaces, or achieving the perfect finish, our grinding capabilities ensure superior quality and accuracy. Profiles upto 7 meter in length and Diameter/Rectangle upto 12 inches can be processed.

Shot Blasting

We offer shot blasting services to clean and prepare the surfaces of aluminium profiles. This process removes impurities and enhances the surface finish, making the profiles ready for further processing.Profiles upto 7 meter in length and Diameter/Rectangle upto 12 inches can be processed.

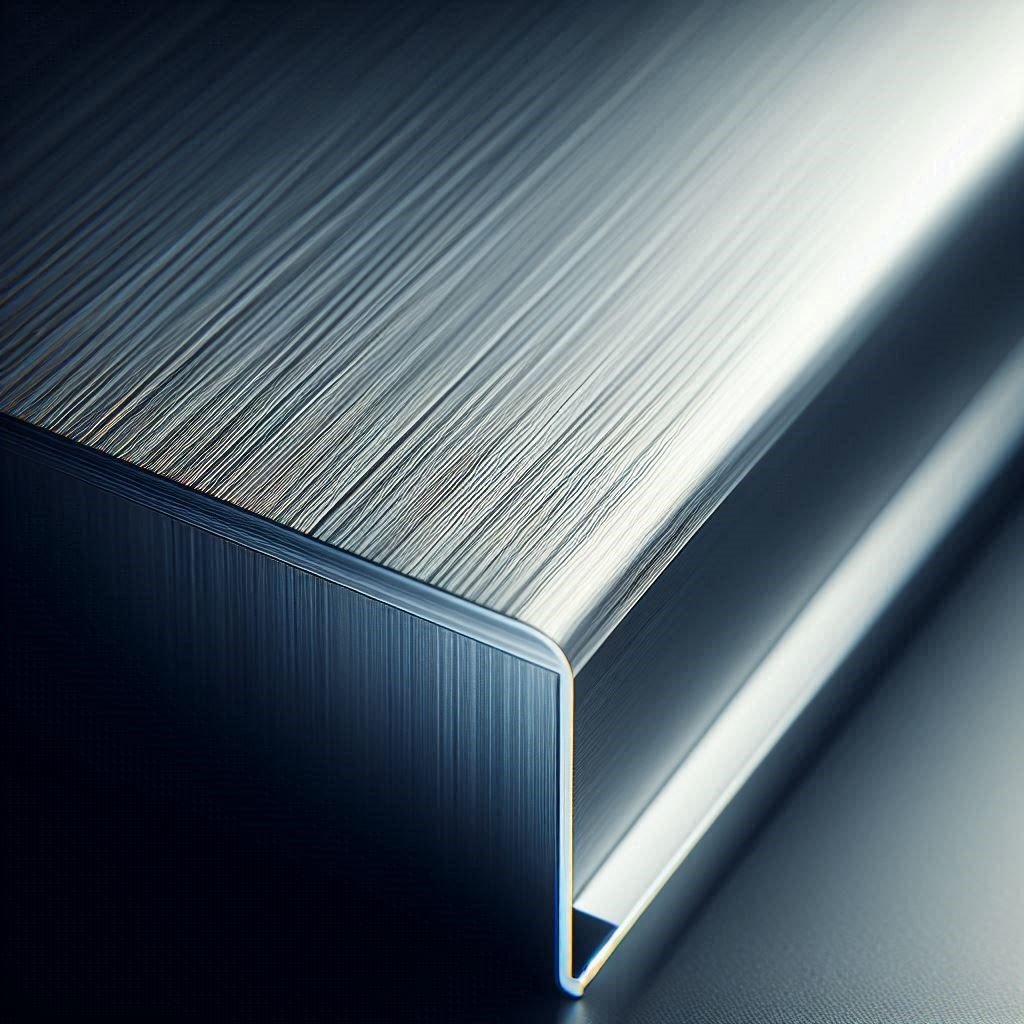

Brushed Finish

Our brushed finish services give aluminium profiles a sleek and modern appearance. This process creates a uniform texture that enhances the aesthetic appeal of the profiles while maintaining their structural integrity. Profiles upto 7 meter in length and Diameter/Rectangle upto 12 inches can be processed.

Hair Line Finish

The hairline finish is another specialized service we offer, providing a fine, linear texture to aluminium profiles. This sophisticated finish is ideal for applications where a refined and elegant look is desired. Profiles upto 7 meter in length and Diameter/Rectangle upto 12 inches can be processed.

3/4/5 axis Complex Machining

At Beyond Lineals, we offer sophisticated 3/4/5 axis complex machining services on aluminium profiles to meet the diverse and intricate requirements of our customers. This advanced machining capability allows for precise and complex geometries, ensuring that even the most demanding specifications are met with accuracy and efficiency. Profiles upto 3 meter in length and Diameter/Rectangle upto 12 inches can be processed.

Anodising

Anodising is a key service we provide to increase the durability and corrosion resistance of aluminium profiles. This electrochemical process creates a protective oxide layer, enhancing the profile’s performance and longevity. Profiles upto 6.5 meter in length and Diameter/Rectangle upto 12 inches can be processed.

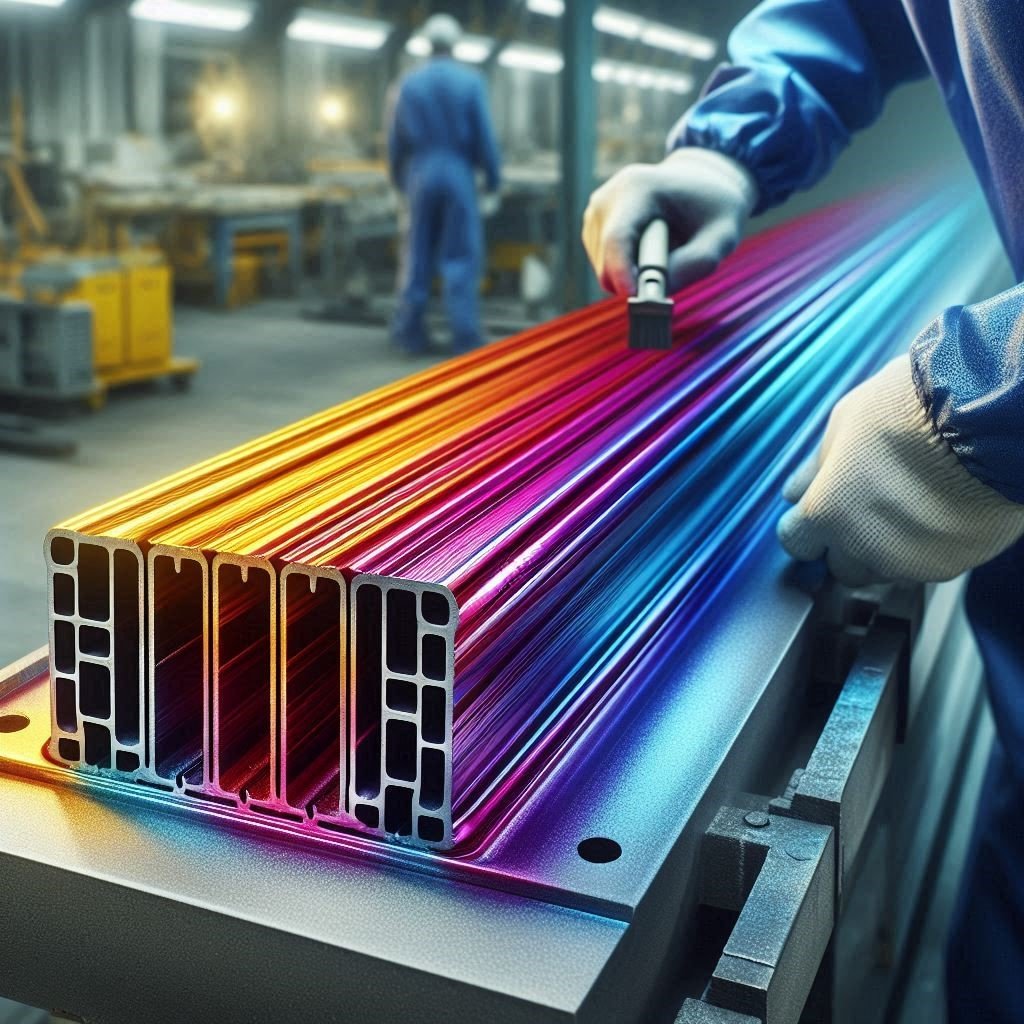

Electro Color

Our electro color services add vibrant and uniform colors to anodized aluminium profiles. This process not only improves the aesthetic appeal but also provides additional protection against environmental factors. Profiles upto 6.5 meter in length and Diameter/Rectangle upto 12 inches can be processed.

Color Dye

Our colour dye services add vibrant and uniform colors to anodized aluminum profiles. Immediately after anodizing, the aluminum is dipped into a bath containing organic or inorganic dyes. These dyes

seep into the microscopic pores of the anodized layer. This process not only improves the aesthetic appeal but also make them visually striking & highly resistant to wear and corrosion, provides additional protection against environmental factors. Profiles up to 6.5 meter in length and Diameter/Rectangle up to 12 inches can be processed.

Painting

Our painting services provide a protective and aesthetic coating to aluminium profiles. We use high-quality paints that ensure long-lasting durability and a beautiful finish, tailored to our customer’s specifications.Various paints like Epoxy , PVDF and others are available. Profiles upto 6.5 meter in length and Diameter/Rectangle upto 12 inches can be processed.

Powder Coating

We utilize powder coating techniques to apply a robust and attractive finish to aluminium profiles. This environmentally friendly process provides excellent resistance to corrosion, wear, and fading, ensuring a long-lasting surface. Profiles upto 6.5 meter in length and Diameter/Rectangle upto 12 inches can be processed.

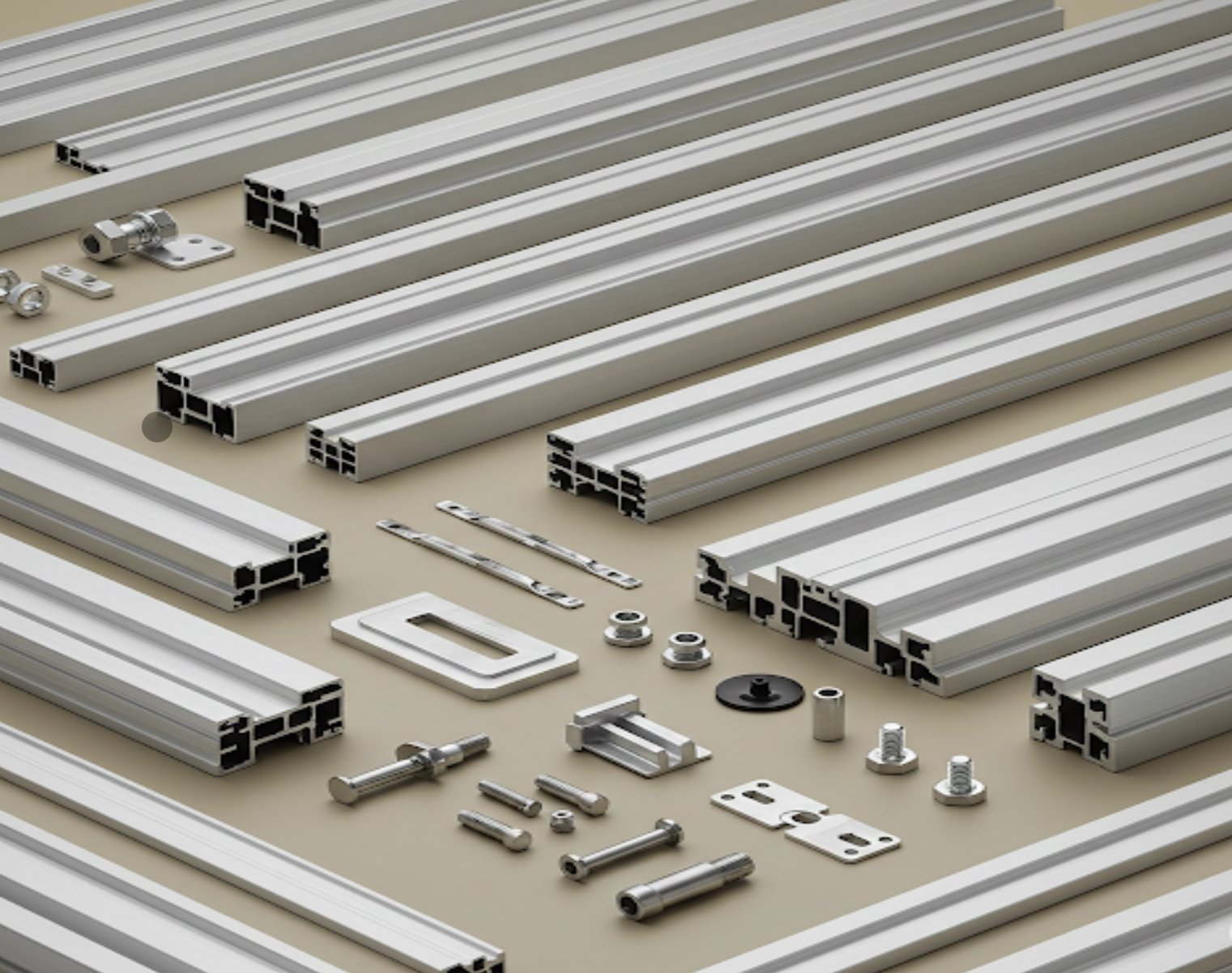

Assembly of Aluminium Extrusion Profiles

The assembly of aluminium extrusion profiles involves integrating hardware and additional products to create versatile components. This process includes attaching brackets, fasteners, and other fittings to the extruded shapes, ensuring structural integrity and functionality. Attention to detail and precision is paramount, as the components must meet specific requirements for various applications, such as construction, automotive, aerospace, and consumer goods. Post-assembly treatments, including anodizing and powder coating, enhance the surface properties and aesthetics of the final product, resulting in durable and customizable aluminium profiles.

Packaging

We understand the importance of proper packaging to protect and preserve the quality of aluminium profiles. Our packaging services are tailored to meet customer demands, ensuring safe and secure delivery of the products.We understand that a profile well delivered in perfection is equally important as a profile well made , hence we take utmost Care in packaging to deliver in Perfection to Any corner of the world.

Ready-to-Use Profiles

Beyond Lineals offers fully finished aluminium profiles and components that are ready to use according to customer specifications. These profiles require no further processing, allowing for immediate application and integration into various projects. Our precision and attention to detail ensure that each profile meets the highest standards of quality and functionality

Customer Satisfaction

At Beyond Lineal’s customer satisfaction is our top priority. We work closely with our clients to understand their needs and deliver tailored solutions that exceed their expectations. Our commitment to quality and service excellence sets us apart in the industry.

At Beyond Lineals, customer satisfaction is not just a goal but the foundation of our business philosophy. We recognize that each client has unique requirements and expectations, and we are dedicated to delivering solutions that not only meet but surpass them. Our process begins with a thorough understanding of our customer’s needs, followed by meticulous planning and execution to ensure that every detail is addressed.

We pride ourselves on our ability to provide high-quality aluminium profiles that are tailored to specific applications. Our state-of-the-art technology and stringent quality control measures guarantee that every product meets the highest standards of excellence. Furthermore, our commitment to transparency and communication ensures that clients are kept informed at every stage of their project, fostering trust and confidence in our services.

Beyond Lineal’s approach to customer satisfaction extends beyond the delivery of superior products. We offer comprehensive support and guidance, ensuring that clients can rely on us for expert advice and solutions. Our dedication to creating long-lasting relationships with our customers is reflected in our high rate of repeat business and referrals. By consistently prioritizing customer satisfaction, Beyond Lineals stands out as a leader in the aluminium processing industry.

Strength

Beyond Lineals continues to lead the way in manufacturing and processing aluminium extruded profiles. Our comprehensive range of services ensures that we can meet the diverse requirements of our customers, providing high-quality products that stand the test of time.

Our unwavering dedication to quality, customer satisfaction, and innovation positions Beyond Lineal’s as the premier choice for aluminium extruded profiles. By integrating state-of-the-art technology with rigorous quality control, we ensure that every product we deliver surpasses the highest standards of excellence. Our tailored packaging solutions further enhance the value we provide, guaranteeing that our profiles reach their destinations in perfect condition, no matter where in the world they are shipped.

Customer satisfaction is the cornerstone of our business philosophy, driving us to exceed expectations with every project. We take the time to understand our client’s unique needs and provide customized solutions that reflect our commitment to excellence. This personalized approach fosters trust and builds long-lasting relationships, evidenced by our high rate of repeat business and referrals.

Beyond Lineal’s comprehensive support and expert guidance ensure that our clients have a reliable partner at every stage of their project. Our transparent communication and dedication to customer service create a seamless experience from start to finish. As we continue to innovate and lead in the aluminium processing industry, our focus remains on delivering exceptional products and experiences that leave our customers thoroughly impressed and eager to return.

Aluminium Extrusion ,machining and aesthetically finished profiles and components.